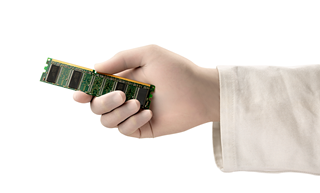

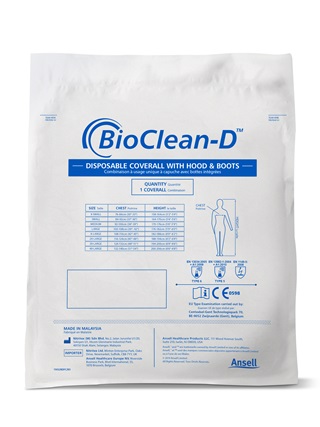

Our range of hand and body PPE solutions includes clean andsterile/non-sterile gloves, coveralls, goggles, aprons and accessories, all designed to protect the product, process, production environmentand personnel. Speak to us to request a sample.

Contact us