Cut resistance in industrial work gloves are measured on a scale of either A1-thru-A9 based on the ANSI/ISEA 105-2016 standard or 0-to-5 or A-thru-F based on the EN388:2016 standard. It is important to understand the protection levels associated with each standard as well as the most appropriate levels for specific applications.

What does the ANSI/ISEA 105-2016 cut standard entail?

The cut resistance standard from the American National Standards Institute (ANSI) and International Safety Equipment Association (ISEA) became effective in North America in March 2016. The updated ANSI/ISEA 105-2016 standard, based on the ASTM F2992-15 testing method, measures cut resistance for Industrial work gloves on a 9-level scale of A1-to-A9. Updated from the ANSI/ISEA 105-2011 standard using a 5-level scale, the current standard allows for more accurate identification of protection in PPE.

The level indicates the capability of the glove to withstand the weight (in grams) until cut-through is achieved. Cut resistance levels of A3 and below have good cut protection and are typically used in applications where cut risk is lower such as hardware assembly, warehouse work and general handling. Cut resistance levels of A4 and above however, are mostly used in applications where the risk of cuts and lacerations is much higher such as handling glass sheets, metal press work or heavy assembly.

What is the EN 388:2016 cut standard?

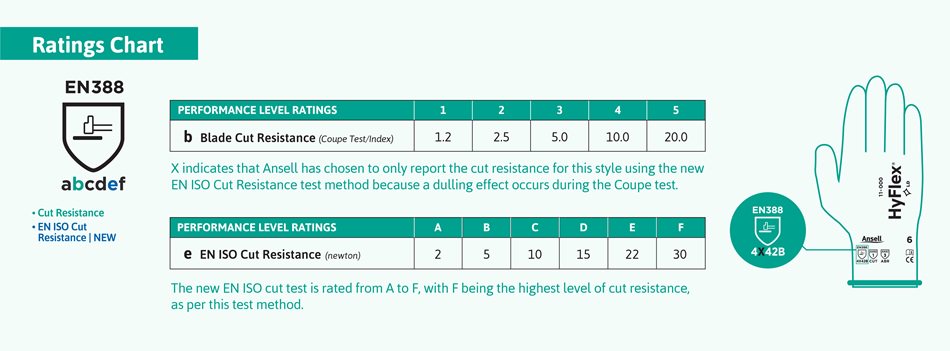

Significant changes were made in 2016 to the EN 388 Mechanical Protection standard. The EN 388 shield pictogram can report up to 6 separate mechanical performance measures. The original Blade Cut test score in position “b” is measured on a scale of 0-to-5 as determined by the EN Coup test. The new EN ISO Cut Resistance score in position “e” measures on a scale of A-to-F based on the ISO 13997 testing method.

EN ISO cut resistance levels are measured in Newtons. The more weight (in Newtons) required to cut through the glove material, the higher the rating.

Are the ANSI/ISEA 105-2016 and EN 388:2016 cut standards the same?

Not exactly…it is extremely important to understand these standards are not equivalent. While both the ANSI/ISEA 105-2016 and EN 388:2016 cut standards are established using the same machines and testing methodologies, the scores are reported in different units of measurement with the former presented as grams (mass) and the latter presented as Newtons (force). A glove that withstands 10 Newtons of force and classified as EN ISO Cut Level C cannot claim to be an ANSI Cut Level A3 without proper testing. See the below section 'How are the tests performed' for further clarification.

How are the tests performed?

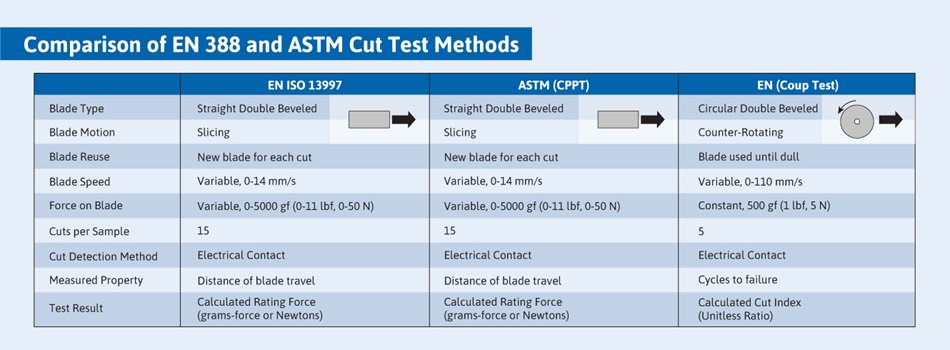

ASTM F2992-15 & EN ISO 13997 Test Methods:

The ANSI/ISEA 105-2016 cut resistance standard is based on the ASTM F2992-15 testing methodology while the EN 388:2016 standard uses the international EN ISO 13997 testing method to measure the ISO Cut Resistance score (position "e"). Both tests can only be performed on the Tomodynamometer Machine, naming it the TDM-100 test, which cuts samples along a straight path by a straight-edged blade under force. However, as mentioned above, although these tests are conducted using the same machine and methodology, the scores are reported differently and cannot be compared as like-for-like.

Coup Test Method:

The original Blade Cut test score (position "b") of the EN 388 standard follows the "Coup Test" which uses an oscillating circular blade at a constant speed to measure the weight (mm) required to cut through the sample material. Unlike with the EN ISO 13997 testing method, the Coup Test scores cannot be directly compared to the ASTM F2992-15 scores.

Adhering to the ASTM F2992-15 & EN ISO 13997 testing methods for each standard will:

- Ensure uniform test results

- Make it easier to compare scores for different materials and products

- Reinforce the compatibility between the two international standards.

Where to find appropriate cut-resistant protection?

Delivering the right hand protection for the right application requires experience and a true understanding of user needs. In addition to determining the appropriate level of cut protection for a given environment, factors such as dexterity, grip and other elements like touchscreen compatibility, puncture resistance, or heat resistance should also be taken into consideration. The best protective solutions are designed expressly for defined tasks.

Pushing the limits of technical innovation, Ansell offers a comprehensive range of high performance work gloves and sleeves options across the full cut level rating gamut. Explore our trusted brands Hyflex®, ActivArmr®, RINGERS® and AlphaTec® to find the right solution for your needs.

Not sure where to start? Ansell has a dedicated staff of Sales experts ready to answer all your questions around mechanical cut protection.